Welcome, manufacturing professionals! In today’s fast-paced and technology-driven world, having the right tools to streamline your operations is essential. Cloud-based Enterprise Resource Planning (ERP) solutions have become increasingly popular for manufacturing companies, offering scalability, flexibility, and real-time insights. In this article, we will explore some of the top cloud ERP solutions tailored specifically for the unique needs of manufacturing businesses.

Top Benefits of Cloud ERP for Manufacturing Industry

Cloud ERP systems offer a multitude of benefits for the manufacturing industry. One key advantage is the ability for manufacturers to access real-time data from anywhere at any time. Traditional on-premise ERP systems require employees to be physically present in the office to access information, which can be limiting in a fast-paced manufacturing environment. With cloud ERP, employees can access data from any device with an internet connection, allowing for greater flexibility and agility in decision-making.

Another important benefit of cloud ERP for manufacturing is scalability. As manufacturing companies grow and evolve, they need a system that can grow with them. Cloud ERP systems can easily scale to accommodate increased data volumes, users, and functionality without the need for expensive hardware upgrades. This flexibility allows manufacturers to adapt to changing market conditions and business needs without disrupting operations.

Cost savings are also a significant advantage of cloud ERP for the manufacturing industry. Traditional on-premise ERP systems require significant upfront investments in hardware, software, and IT infrastructure. In contrast, cloud ERP systems operate on a subscription-based model, which can result in lower initial costs and predictable monthly expenses. Additionally, cloud ERP eliminates the need for costly IT maintenance and upgrades, as these tasks are handled by the cloud provider.

Collaboration and visibility are enhanced with cloud ERP systems, allowing manufacturers to streamline communication and information sharing across departments and locations. Cloud-based platforms enable real-time collaboration on production schedules, inventory levels, and supply chain management, leading to improved efficiency and productivity. Manufacturers can also gain greater visibility into their operations with advanced reporting and analytics tools that provide insights into performance and trends.

Data security is a top priority for manufacturers, and cloud ERP systems offer robust security features to protect sensitive information. Cloud providers invest heavily in cybersecurity measures, such as encryption, firewalls, and data backup, to safeguard against cyber threats and data breaches. Manufacturers can have peace of mind knowing that their critical data is secure and compliant with industry regulations.

In conclusion, cloud ERP systems offer numerous benefits for the manufacturing industry, including real-time access to data, scalability, cost savings, collaboration, visibility, and data security. By leveraging the power of the cloud, manufacturers can optimize their operations, improve decision-making, and drive business growth in an increasingly competitive market.

Factors to Consider when Choosing a Cloud ERP for Manufacturing

When selecting a Cloud ERP solution for your manufacturing business, there are several key factors to consider to ensure that you choose the best option for your specific needs. Here are some important considerations to keep in mind:

1. Industry-specific functionality: One of the most crucial factors to consider when choosing a Cloud ERP for manufacturing is whether the system offers industry-specific functionality. Manufacturing processes can vary greatly depending on the type of products being produced, so it is important to find a solution that can support the unique requirements of your particular industry. Look for a system that offers features such as bill of materials management, work order tracking, and inventory optimization tools that are tailored to the needs of manufacturers.

2. Scalability: Another important factor to consider when selecting a Cloud ERP for manufacturing is scalability. As your business grows and evolves, your ERP system needs to be able to grow with you. Make sure that the system you choose can easily accommodate future expansion and increased complexity without requiring a complete overhaul of your existing processes. Look for a solution that offers flexible pricing options and the ability to add new users, modules, and features as needed.

3. Integration capabilities: A Cloud ERP system for manufacturing should seamlessly integrate with your existing systems and applications to ensure smooth and efficient operations. Look for a solution that offers easy integration with popular software tools such as CRM systems, accounting software, and production scheduling tools. This will help streamline your processes and minimize the need for manual data entry, reducing the risk of errors and improving overall efficiency.

4. Data security: The security of your data is a top priority when selecting a Cloud ERP system for manufacturing. Make sure that the solution you choose includes robust security features such as encryption, access controls, and regular data backups to protect your sensitive information from cyber threats and unauthorized access. Additionally, look for a provider that complies with industry standards and regulations to ensure that your data is handled in a secure and compliant manner.

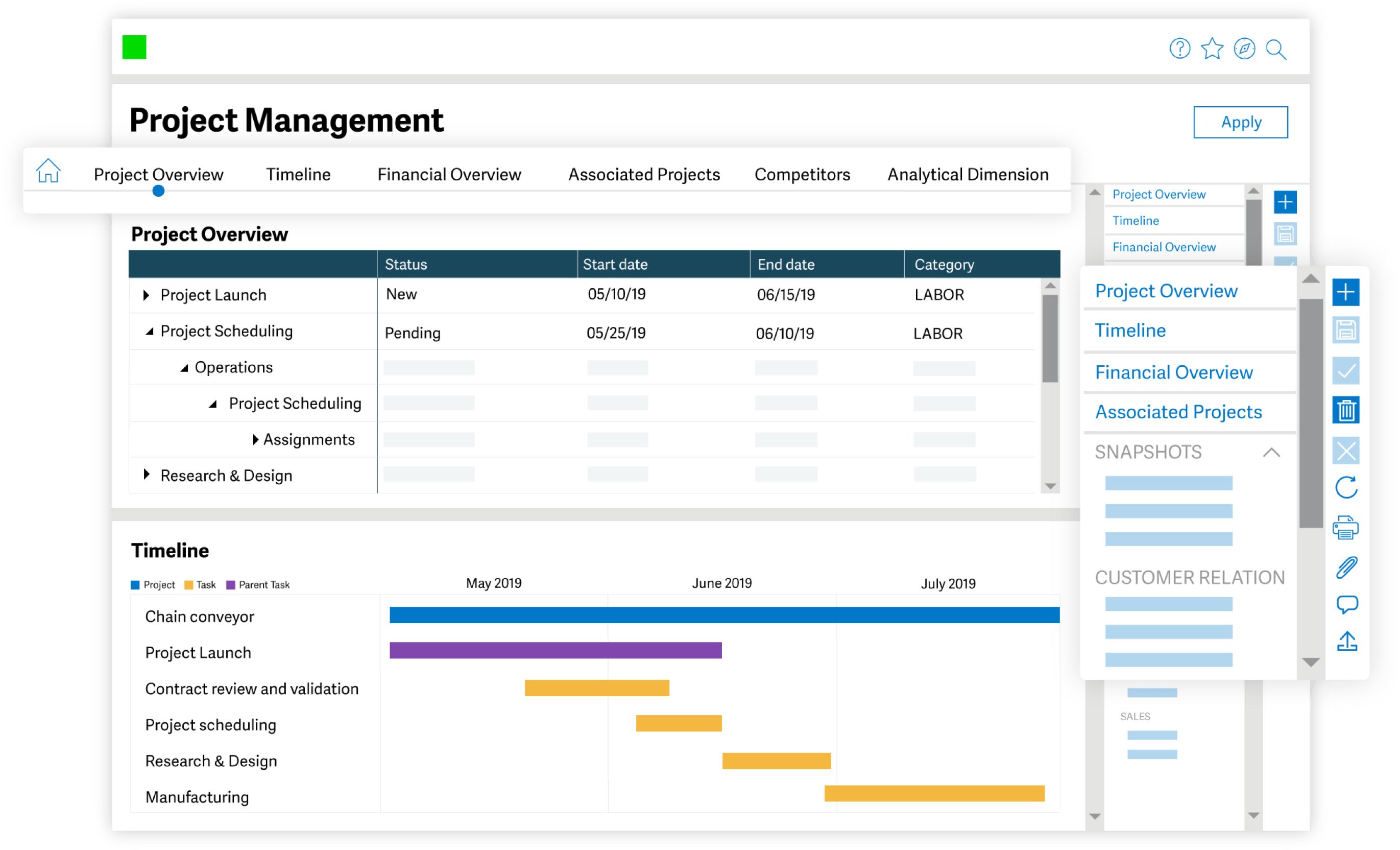

5. User-friendly interface: Ease of use is another important factor to consider when choosing a Cloud ERP for manufacturing. Your employees will need to be able to quickly learn how to use the system and navigate its features in order to maximize productivity. Look for a solution that offers an intuitive interface, customizable dashboards, and comprehensive training and support resources to ensure that your team can easily adopt and make the most of the new system.

By considering these key factors when choosing a Cloud ERP for manufacturing, you can select a solution that meets your specific needs and helps your business thrive in today’s competitive manufacturing landscape. Take the time to evaluate your options carefully and choose a system that aligns with your goals and objectives for the future.

Key Features to Look for in a Cloud ERP Solution for Manufacturing

When searching for the best cloud ERP solution for manufacturing, there are several key features that you should look for to ensure that the software meets the specific needs of your industry. These features can help streamline processes, improve efficiency, and boost overall productivity. Here are some key features to consider:

1. Inventory Management: One of the most critical aspects of manufacturing is managing inventory effectively. Look for a cloud ERP solution that offers robust inventory management capabilities, including real-time tracking of raw materials, work-in-progress, and finished goods. The software should also provide tools for demand forecasting, inventory optimization, and automated replenishment to ensure that you always have the right inventory levels on hand.

2. Production Planning and Scheduling: A cloud ERP solution for manufacturing should have advanced production planning and scheduling tools to help you optimize production processes, minimize downtime, and meet customer demand. Look for features such as capacity planning, production tracking, and order management to streamline operations and improve efficiency on the shop floor.

3. Quality Control and Compliance: Quality control is a crucial aspect of manufacturing to ensure that products meet stringent quality standards and comply with industry regulations. When choosing a cloud ERP solution, it is essential to look for robust quality control and compliance features. The software should offer tools for implementing quality checks at various stages of the production process, tracking quality metrics, and conducting root cause analysis in case of quality issues. Additionally, the ERP solution should help you comply with industry-specific regulations and certifications to maintain product quality and safety.

By selecting a cloud ERP solution that offers these key features, you can streamline your manufacturing operations, improve efficiency, and stay competitive in today’s fast-paced market. Take the time to evaluate different ERP software options and choose a solution that aligns with your specific manufacturing needs and goals.

Case Studies: Success Stories of Manufacturers Using Cloud ERP

1. ABC Manufacturing: ABC Manufacturing is a leading furniture manufacturer that implemented a cloud ERP system to streamline their business operations. The company saw a significant improvement in their production efficiency and reduced costs by automating their inventory management and order processing. With real-time data insights, ABC Manufacturing was able to make informed decisions and adapt quickly to changing market demands, leading to increased customer satisfaction and improved overall profitability.

2. XYZ Electronics: XYZ Electronics, a well-known electronics manufacturer, turned to cloud ERP to modernize their outdated systems and improve collaboration between their multiple production facilities. By migrating to a cloud-based solution, XYZ Electronics was able to centralize their data, standardize processes, and enhance communication across all departments. As a result, they experienced a 20% reduction in lead times, improved inventory accuracy, and increased on-time delivery rates, leading to a boost in customer retention and revenue.

3. DEF Automotive: DEF Automotive, a global automotive parts manufacturer, faced challenges with maintaining accurate production schedules and managing complex supply chain processes. By implementing a cloud ERP system, DEF Automotive gained visibility into their entire manufacturing operations, enabling them to optimize inventory levels, reduce production lead times, and enhance supplier collaboration. As a result, DEF Automotive was able to improve production efficiency by 30% and reduce manufacturing costs by 15%, leading to increased competitiveness in the market.

4. GHI Pharmaceuticals: GHI Pharmaceuticals, a pharmaceutical manufacturer, struggled with outdated legacy systems that hindered their ability to comply with strict regulatory requirements and manage their complex manufacturing processes. With the implementation of a cloud ERP solution, GHI Pharmaceuticals achieved regulatory compliance, improved batch tracking and traceability, and enhanced quality control measures. This not only resulted in GHI Pharmaceuticals meeting industry standards but also increased their production output by 25% and reduced errors in the manufacturing process.

Future Trends in Cloud ERP Adoption for Manufacturing Sector

In recent years, the manufacturing sector has seen a significant shift towards cloud-based ERP systems. As technology continues to advance, the future trends in cloud ERP adoption for the manufacturing sector are evolving rapidly.

1. Integration of IoT

One of the key future trends in cloud ERP adoption for the manufacturing sector is the integration of IoT (Internet of Things) technology. IoT devices such as sensors and connected machines can provide real-time data that can be seamlessly integrated into cloud ERP systems. This integration allows manufacturers to have more visibility and control over their production processes, leading to greater efficiency and productivity.

2. AI and Machine Learning

Another trend in cloud ERP adoption for manufacturing is the incorporation of artificial intelligence (AI) and machine learning capabilities. These technologies enable ERP systems to analyze data, predict trends, and automate processes. By utilizing AI and machine learning, manufacturers can make more informed decisions, optimize resources, and improve overall performance.

3. Enhanced Data Security

With the increasing adoption of cloud ERP systems, data security has become a top priority for manufacturers. Future trends in cloud ERP adoption for manufacturing will focus on enhancing data security measures to protect sensitive information from cyber threats. Manufacturers will continue to invest in robust security protocols and encryption techniques to keep their data safe and secure in the cloud.

4. Mobile Accessibility

Mobile accessibility is another key trend in cloud ERP adoption for the manufacturing sector. With the rise of remote work and the need for real-time data access, manufacturers are demanding ERP systems that can be accessed from anywhere, at any time, on any device. Future cloud ERP systems will prioritize mobile accessibility, allowing manufacturers to stay connected and make informed decisions on-the-go.

5. Industry-specific Solutions

One of the most significant future trends in cloud ERP adoption for manufacturing is the emergence of industry-specific solutions. As the manufacturing sector becomes more diverse and specialized, ERP systems will need to adapt to meet the unique needs of different industries. Cloud ERP providers will offer customizable solutions tailored to specific manufacturing verticals, such as automotive, aerospace, or pharmaceuticals. These industry-specific solutions will provide manufacturers with the tools and functionalities they need to succeed in their specific market.

In conclusion, the future trends in cloud ERP adoption for the manufacturing sector are shaping the way manufacturers operate and manage their businesses. From integrating IoT devices to utilizing AI and machine learning capabilities, manufacturers are adopting cloud ERP systems to stay competitive and innovative in today’s rapidly evolving market.

Originally posted 2025-04-07 15:26:17.